The 1st precision mold processing technology: CNC milling

Date:2019-10-28Article editor:Starting Point PrecisionViews:5645

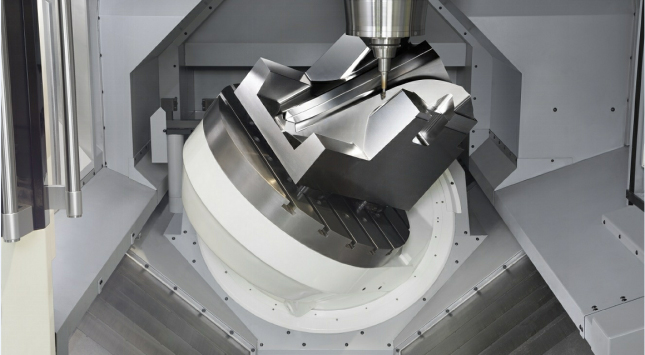

It is straightforward to say that the rapid development of the plastic mold manufacturing industry is mainly due to the innovative application of CNC milling technology. From the traditional milling machine to the three-axis machining center, and now to the five-axis high-speed milling, almost all the complicated three-dimensional surface parts can be processed, and the hardness of the material is no longer a bottleneck. The main cavities and profiles of plastic mold parts are completed by CNC milling.

High-speed milling uses small-diameter milling cutters (typical cutters are solid carbide ball-end milling cutters, end mills and corrugated milling cutters), high speed (spindle speeds up to 40,000 rpm), and small cycle feeds for high productivity The amplitude is increased, the accuracy can be stabilized to 5μm; at the same time, due to the low milling force, the workpiece has less thermal deformation, less milling depth, and faster feed (linear motor, fast moving speed of up to 80m/min, up to 2g acceleration), surface The finish can reach Ra<0.15 μm. High-speed milling can process 60HRC hardened die steel parts, so high-speed milling allows the parts to be machined after heat treatment, which greatly simplifies the mold manufacturing process.

Foreign advanced CNC milling equipment manufacturers include Swiss GF processing program, German DMG, German Hamer, Japanese Makino, German Rhodes, German OPS, German giant wave, German Intex, Japan Yamazaki Mazak, Japan Hey, American Haas, etc.

Copyright © 2019 All Rights Reserved Dongguan Starting Point Precision Technology Co., Ltd. Tel: +86-769-82855591

Add: No. 277 Zhen'an Middle Road, Chang'an Town, Dongguan, Guangdong, China