The 4th precision mold processing technology: Grinding

Date:2019-10-24Article editor:Starting Point PrecisionViews:4173

Grinding machines are precision equipment for finishing the surface of parts, especially hardened parts. Grinding machines used in mold processing are mainly surface grinders, universal internal and external cylindrical grinders, coordinate grinding machines, and PG (optical curve grinders).

The small flat grinding machine is mainly used to process small-sized mold parts, such as precision inserts, precision molds, and sliders. Large water grinders are often used for larger size stencil processing. Nowadays, the speed of the surface grinding wheel and the speed of the table movement have become a common trend. Due to the use of advanced functional components such as linear guides, linear motors and static pressure screws, the speed of movement has been greatly improved, and it has been continuously improved. Grinding wheel dressing technology. The vertical feed of the grinding head can be as small as 0.1μm, the grinding surface roughness Ra<0.05μm, the machining precision can be controlled within 1μm, and the super-fine grinding processing is realized.

The foreign advanced grinding machine equipment manufacturer is represented by the Schleifring Group. It has acquired many of the world's top grinding machine manufacturers, including STUDER, BLOHM, MAEGERLE, and Joan. JUNG, SCHAUD, MIKROSA, EWAG and WALTER. Schleifring's well-known companies produce different types of grinding machines and offer comprehensive grinding solutions. In the domestic precision mold factory, most of the surface grinding machines use Japanese surface grinders, such as the Okamoto grinding machine in Japan.

Mold revolving parts, with high precision requirements, good surface finish, and even complex curved parts, need to be completed with high-precision cylindrical grinders, such as Huff insert parts for preform injection molds. Grinding with a high-speed rotating grinding wheel can process materials with higher hardness, such as hardened die steel and hard alloy. Swiss Stuart universal internal and external grinding machines are designed for medium-sized single parts and batch workpiece grinding. They are suitable for customizing individual requirements (circular grinding, non-circular grinding, thread grinding, internal grinding) .

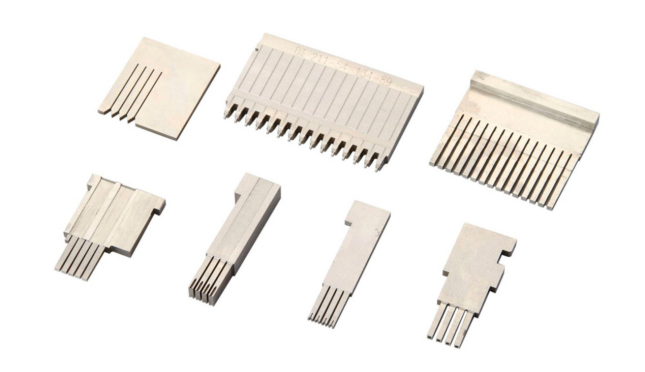

The optical curve grinder can grind grooves with high distance accuracy and various contour shapes. With the plotter, the plotter plots the desired image on the film, the film is attached to the projection screen and corrected, and the processor will shape the film according to the molding on the film. Optical projection grinding is suitable for the forming of high-hardness materials, such as tungsten or hard alloy workpieces, and occasionally high-speed steel workpieces. Generally, the connector die is used for the blade and the punch, the terminal, the precision half stroke punch, the lower die block and the stripping plate and the like.

The more famous optical curve grinding machines are Swiss HAUSER, American MOORE, and Japanese AMADA. The maximum speed of the spindle of Japan AMADA optical curve grinder can reach 30,000 rpm, the processing precision is within 2μm, the minimum internal R angle of processing is R0.03mm, the outer R angle is R0.02mm, and the thinnest part of the processed shaped punch can reach 0.06mm, the groove depth to diameter ratio of the processed groove is about 2:1, and the surface roughness Ra can reach 0.025μm.

Copyright © 2019 All Rights Reserved Dongguan Starting Point Precision Technology Co., Ltd. Tel: +86-769-82855591

Add: No. 277 Zhen'an Middle Road, Chang'an Town, Dongguan, Guangdong, China